How Digital Twins Are Enhancing Asset Performance Management

Asset performance management (APM) is the process of optimizing the performance and maintenance of physical assets such as machines, equipment, and buildings to improve operational efficiency, reduce downtime, and increase productivity. With the advent of digital copies, APM has entered a new era of enhanced visibility and insight.

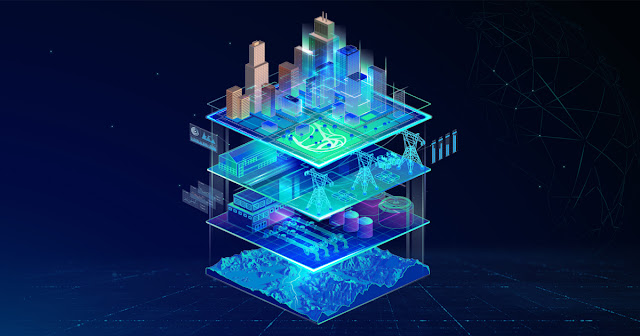

A Digital Twin is a virtual replica of a physical asset, process, or system that uses real-time data to simulate, predict, and optimize performance. By creating a digital copy of an asset, APM professionals can gain a better understanding of its behavior and performance, identify potential issues before they occur, and optimize maintenance and repair activities.

One of the key advantages of digital copies in APM is the ability to monitor asset performance in real-time. By connecting sensors and other monitoring devices to an asset, data can be collected and analyzed to provide insights into its behavior and performance. This data can then be used to identify potential issues, such as wear and tear on components, and predict when maintenance or repair activities are needed.

The main issue impeding the growth of the global Digital Twin Market is the high initial cost of deployment, which involves substantial investments in IoT infrastructure.

Digital copies can also be used to simulate different scenarios and optimize asset performance. By adjusting various parameters, such as operating conditions and maintenance schedules, APM professionals can simulate different scenarios to identify the most efficient and effective way to operate an asset. This can help reduce downtime, increase productivity, and extend the lifespan of the asset.

Another advantage of Digital Twin is their ability to enable remote monitoring and control. By creating a virtual replica of an asset, APM professionals can monitor its performance from anywhere in the world, using data and analytics to identify potential issues and take corrective action. This can help reduce the need for onsite inspections and maintenance, and enable faster response times to issues that do occur.

Digital copies can also help optimize maintenance and repair activities. By predicting when maintenance or repair activities are needed, APM professionals can schedule them at a time that minimizes disruption to operations. Digital copies can also help identify the root cause of issues, enabling APM professionals to take corrective action that addresses the underlying problem rather than just treating the symptoms.

By identifying problems and improving litigation, investigations, and regulatory preparation, Digital Forensics is a multidimensional process that assists corporate organisations in streamlining and simplifying their business processes.

In addition to these benefits, digital copies can also help improve safety and reduce risk. By simulating different scenarios, APM professionals can identify potential safety hazards and take steps to mitigate them. Digital copies can also help identify potential risks, such as equipment failure or environmental hazards, and develop strategies to manage them.

Digital Twin are revolutionizing APM by providing enhanced visibility and insight into asset performance. By creating a virtual replica of an asset, APM professionals can monitor its performance in real-time, simulate different scenarios to optimize performance, enable remote monitoring and control, optimize maintenance and repair activities, and improve safety and reduce risk. As the technology continues to evolve, it is expected to become an increasingly important tool in the APM toolbox.

Comments

Post a Comment